Knowledge base » Articles » PLM – Process operation or operation process?

PLM – Process operation or operation process?

In the Product Lifecycle Management (PLM) context, a ‘Process of Action’ can be understood as the series of steps taken during a specific operational procedure. On the other hand, ‘Action of Process’ might refer to the tasks carried out and decisions made to improve and optimize these operating procedures.

We often don’t think about it as we struggle with many daily tasks, checking off items on our to-do lists without considering if we could do things better, faster, or more efficiently.

One more concept should be added to the above title: process thinking.

“…But Magda, it’s a theory, and we need management practice…”

That’s right, and this theory is about the practice of management, specifically:

· About the management of the process itself and the product,

· How the management process is conducted and how the chosen tools, such as spreadsheets or PLM systems, impact it.

· About product management optimization.

· And finally, how to improve the quality of work and the quality of the product itself.

Let’s start from the beginning, with the fact that everything we do involves a process. There is always a beginning, a starting point initiated by us, or some independent event, and … the ending point, which is the effect we expect.

To achieve our desired end, we consistently execute tasks and decisions. Sometimes, it’s easy, yet sometimes, it is strewn with difficulties. However, the results are from combining action processes and process-based thinking.

So, what is the difference between operation process and process operation?

In a very brief way:

· The operation process is … 😊strictly operational. It describes the sequence of activities that make up this action. In other words, this is the path we consequently follow.

· Process operation focuses on management and refers to the tasks performed and decisions made to improve and optimise processes. Simply put, it influences the final shape of the chosen path.

· Process thinking is a strategic approach that assumes that processes are critical elements of the organization and should be optimized for better results. It includes a visionary and creative aspect and anticipates the factors influencing the process and how they can be changed to give better results.

Is creating a new product a process?

I don’t think anyone has any doubts about that. Initially, there is only an idea or a drawing, which transforms into the expected effect — the final product due to many steps and tasks. The same is true for the rest of the product life cycle.

In managing these, we undertake operational activities, using various tools for support. Usually, these are ubiquitous spreadsheets such as Excel or dedicated Product Lifecycle Management systems (PLM, PIM or PDM).

There are many ways to create a new product. Therefore, there are many process paths associated with it. All of them end with the achievement of the goal.

But they differ in the course, the number of necessary activities, the number of people involved, the costs, the number of potential errors and the final quality assessment of the product obtained.

One element that affects the process’s length and complexity is the tool used.

The decision to choose and to use one results from process thinking and the ability to predict its impact on the process. It influences the entire organisation, regardless of whether we understand it as the whole company or a product department only.

So, what exactly is process thinking in product management?

It offers three-fold benefits, addressing three seemingly contradictory perspectives.

· Firstly, looking at the product from the customer’s level, apart from the need, also means quality, time, and price.

· A look at the individual stages of activities from the level of the employee, which means simplicity, intuitiveness, and time.

· Finally, it’s the manager’s view of all activities: smoothness, quality, time, price, control of work at all stages and sales.

“But Magda, we were supposed to talk about tools…”

And that’s what we’re talking about because consistent and simultaneous achievement of all three perspectives is possible only in PLM systems.

Anyway, let’s do a little comparison…

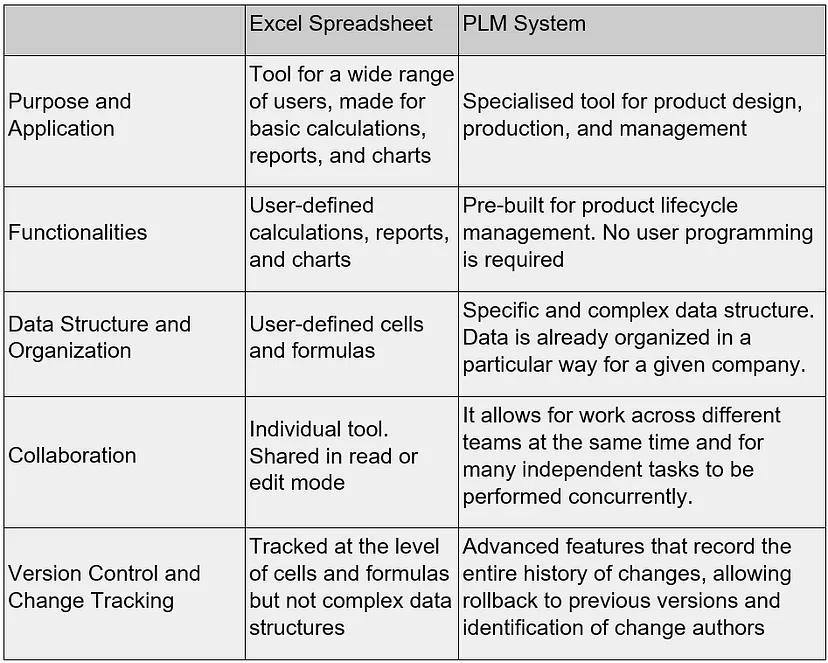

Process management in Excel and the PLM system

Undeniably, Excel, like many other spreadsheets, is a great tool, but is it sufficient for product management?

“ But Magda, after all, this comparison does not show three perspectives of looking at product life cycle management…”

On the contrary!

As dedicated software for teams working on new and launched products, PLM systems eliminate virtually all the problems employees face using spreadsheets daily.

Moreover, thanks to this, PLM systems, such as @SilkPLM, allow you to see and deliver what is essential to the customer.

How does the Product Lifecycle Management system improve work?

1. PLM organises the work of a single user.

All available functionalities are self-explanatory, making them intuitive and easy to use. This directly translates into the time necessary to complete them and carry out subsequent steps in the process. In addition, a single user can collaborate with other team members without collisions.

The user does it without even thinking about it because each completed activity is automatically notified to the person whose tasks are next in the process. In this way, the system facilitates and speeds up work, making it easy to perform with little effort. So, we have a fulfilled employee’s perspective.

2. The PLM system streamlines and accelerates work on the product.

Speed translates into price and ease into the quality of work.

In addition, this quality is monitored by budgets, schedules, calendars and related alerts that remind, urge, inform or alarm, depending on what they concern. Thanks to them, mistakes can be caught faster, and authors can be notified about it. So, corrective actions can be introduced more effectively.

As a result, the entire process is completed faster, easier and with full supervision, which saves us time and money and is the quintessence of the manager’s perspective.

3. PLM improves quality, and thus, you gain the respect of the customer.

The customer’s perspective is the last one because it depends directly on the product. The better, cheaper and more attractive the product, the greater customer satisfaction, and good products are created when working on them is easier and more pleasant.

Therefore, the process’s smoothness, agility, and simplicity translate directly into the quality, price, and delivery time of the new product. So, we have a 3rd perspective fulfilled.

On the other hand, we must remember that our environment is constantly changing. Nowadays, it’s not sufficient for the fashion industry to produce high-quality and appealing products; it must also demonstrate that its products are ecologically safe. This makes things more challenging for producers.