Knowledge base » Articles » AI For Furniture Design

What is Planning and Allocation in Retail?

Planning and allocation are the procedures that guarantee the timely delivery of the correct items to the proper locations. Demand forecasting, inventory distribution, and data-driven decision-making are all part of these processes. Waste is minimized, stockouts are reduced, and earnings are optimized when merchants employ efficient planning and allocation. Streamlining processes and enhancing customer happiness are two of these activities’ primary impacts on a company’s bottom line in the fast-paced retail industry.

Understanding Retail Planning

AI for furniture design uses complex algorithms and machine learning to make furniture that fits the wants and tastes of the user.

Retail planning is projecting customer demand and creating plans of action to satisfy that desire. It includes price policies, inventory control, and sales projections. Retailers use various tools, including historical data, market trends, and customer insights, to forecast the type and quantity of products they should stock.

Fashion industry especially find this difficult as customer tastes are greatly influenced by seasonal variations and quick-moving trends. By preventing either overstocking or understocking, a good retail planning system helps stores to balance demand with supply.

The Role of Allocation in Retail

Allocation starts when a retail plan is made. Allocation guarantees that, depending on variables such location-specific demand, store size, and client demographics, the correct items are sent to the correct outlets. It involves analyzing sales data, understanding local preferences, and keeping an eye on stock levels in each store to maintain optimal inventory.

Example:

A business in a colder countries, could need more winter clothing whereas one in a warmer one might need more summer clothing. Allocation guarantees that every shop has the products its consumers most likely to buy, thereby enabling this sort of customized strategy.

How Planning and Allocation Enhance Retail Efficiency

When done effectively, allocation and planning may greatly lower inefficiencies. These processes enable retailers to avoid excess inventory, which ties up capital and requires storage, and prevent stockouts that lead to missed sales opportunities.

For brands working in multiple locations, effective planning and allocation help streamline operations, allowing for more predictable cash flow and better resource management.

Why Planning and Allocation Matter for the Future of Retail

As consumer preferences continue to shift and competition in the retail space increases, effective planning and allocation will only grow in importance. Brands that invest in technology, such as PLM systems, to optimize these processes will be better positioned to meet customer expectations, streamline their supply chains, and improve profitability.

For retail companies, staying ahead of the curve requires both strategic foresight and the right tools. SilkPLM offers a range of features that not only simplify the planning and allocation process but also bring AI-driven insights to the forefront, empowering brands to stay agile in a rapidly changing market.

Conclusion

Planning and allocation are key components of a successful retail strategy. By accurately predicting demand and distributing products efficiently, retailers can improve profitability and customer satisfaction. With the help of technology like SilkPLM, these processes become even more precise, allowing retailers to stay competitive and responsive in an evolving industry.

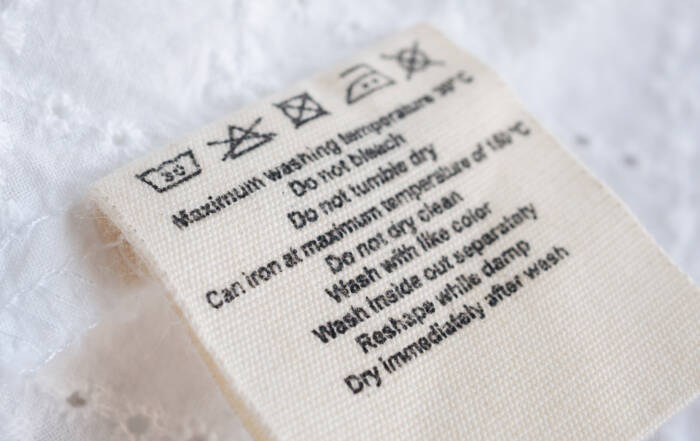

Fashion Labels: The Essential Guide for Clothing Brands

Fashion labels play a crucial role in your brand and shape how customers perceive your product. If you're launching a new product line and feel unsure about how to select the right labels, this guide will serve as your go-to resource!

Guide to Care Labels for Fashion Brands: Compliance & Sustainability

Care labels are a vital communication tool for customer satisfaction, legal compliance, and reinforcing your brand values. Whether you're a fashion startup, e-commerce business, or independent designer, understanding care labels is non-negotiable.

Author:

Mariusz Wilczek

Marketing Specialist at SilkPLM