Knowledge base » Articles » The Key Features of a Modern PLM System: Optimizing Product Life Management

The Key Features of a Modern PLM System: Optimizing Product Life Management

Launching new products is a process consisting of many stages. Their proper planning affects the profitability of the investment and can also be a way to achieve success in a competitive market. To achieve this, you should consider using a modern PLM system, which supports people in a better organization of daily work on a product.

What should you know about PLM systems? Why should you use them and what should they be distinguished by to optimize the product lifecycle?

![]()

PLM system – how does it work?

A Product Lifecycle Management stands for PLM. It refers to a coherent product strategy, planned for all stages of its life, such as:

- design,

- production,

- market launch,

- modifications,

- recall.

Effective PLM system handles all production and distribution-related challenges, that is, the manufacturing facility, sub-suppliers, logistics, transportation, and storage.

On the other side, it also makes use of consumer market data and target customer viewpoints. All of this is done to produce products that exactly meet the present demand, therefore raising a brand’s market competitiveness.

All product data goes into a single integrated database within the PLM system, that enables not only storage and grouping but also management and analysis of it to help to deduce future prospective development routes.

![]()

PLM system – benefits for the company

What can you gain by implementing dedicated product lifecycle management software into your company?

It’s an effective way for multifaceted optimization of numerous processes, related to production. The main thing you gain from it is a reduction of costs and the time it takes to launch a product onto the market.

Also, it is easier to control any changes and implement modifications in the design to respond to the real needs of customers. This, of course, improves the quality of the product.

Learn more about PLM system benefits by clicking here.

![]()

Key Features of an Effective PLM System

Let us now list all the most critical tasks and process components the PLM system should support. This will be useful when you are considering a system for your company!

Comprehensive Lifecycle Coverage

- Design and conceptualization

- Production and manufacturing

- Market launch strategies

- Product modifications and updates

- End-of-life management and recall processes

Integrated Data Management

- Centralized database for all product information

- Real-time data updates and synchronization

- Efficient data storage, grouping, and analysis

Supply Chain Integration

- Seamless coordination with manufacturing plants

- Sub-supplier management

- Logistics and transportation optimization

- Inventory and storage control

Cost and Time Reduction

- Streamlined processes for faster time-to-market

- Efficient change management and design modifications

- Data-driven decision making for cost optimization

Quality Improvement

- Enhanced product quality through data-driven insights

- Easier implementation of customer-driven improvements

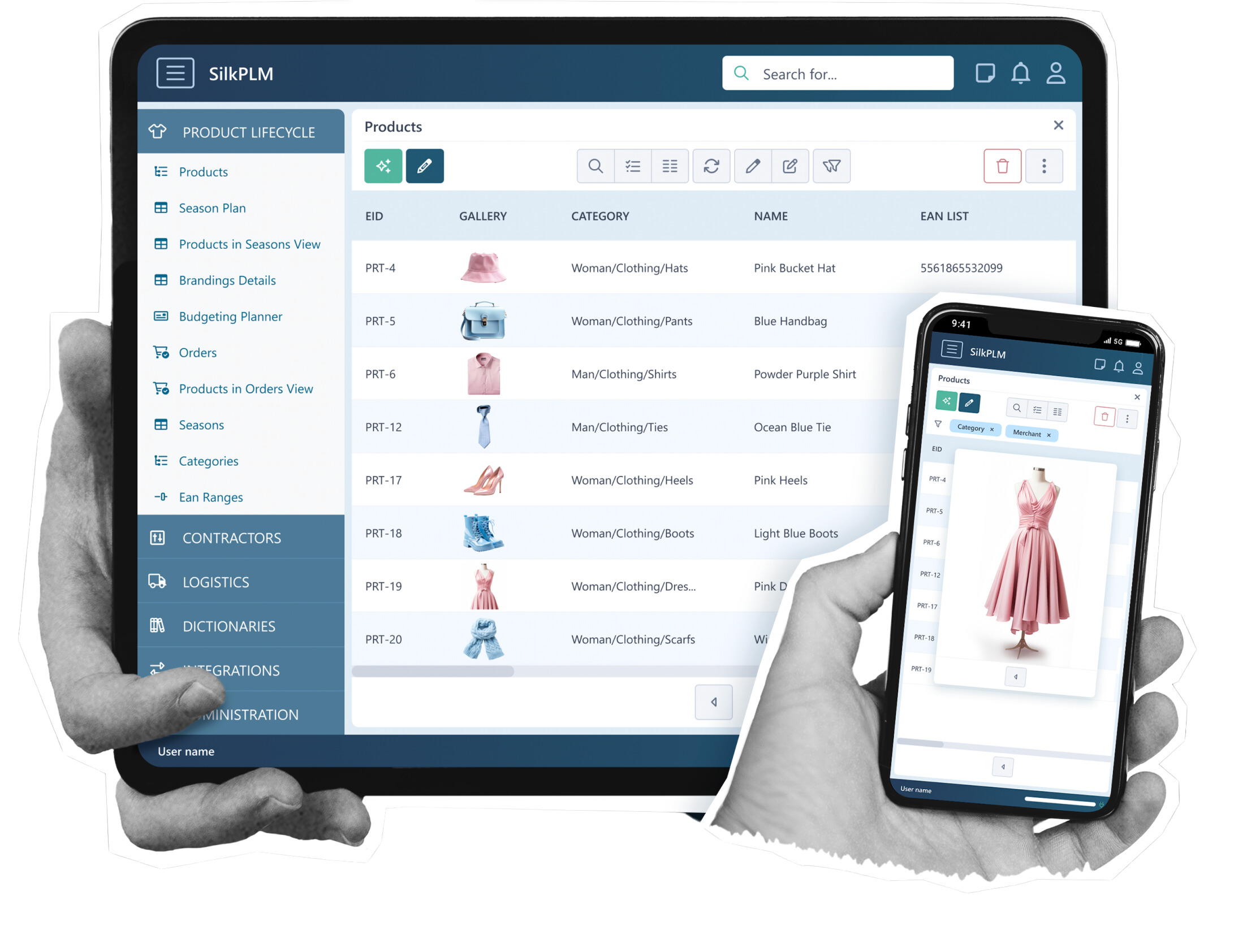

Cloud-Based Accessibility

- Remote access to product data from anywhere

- Improved team collaboration and communication

![]()

What SilkPLM brings to the table

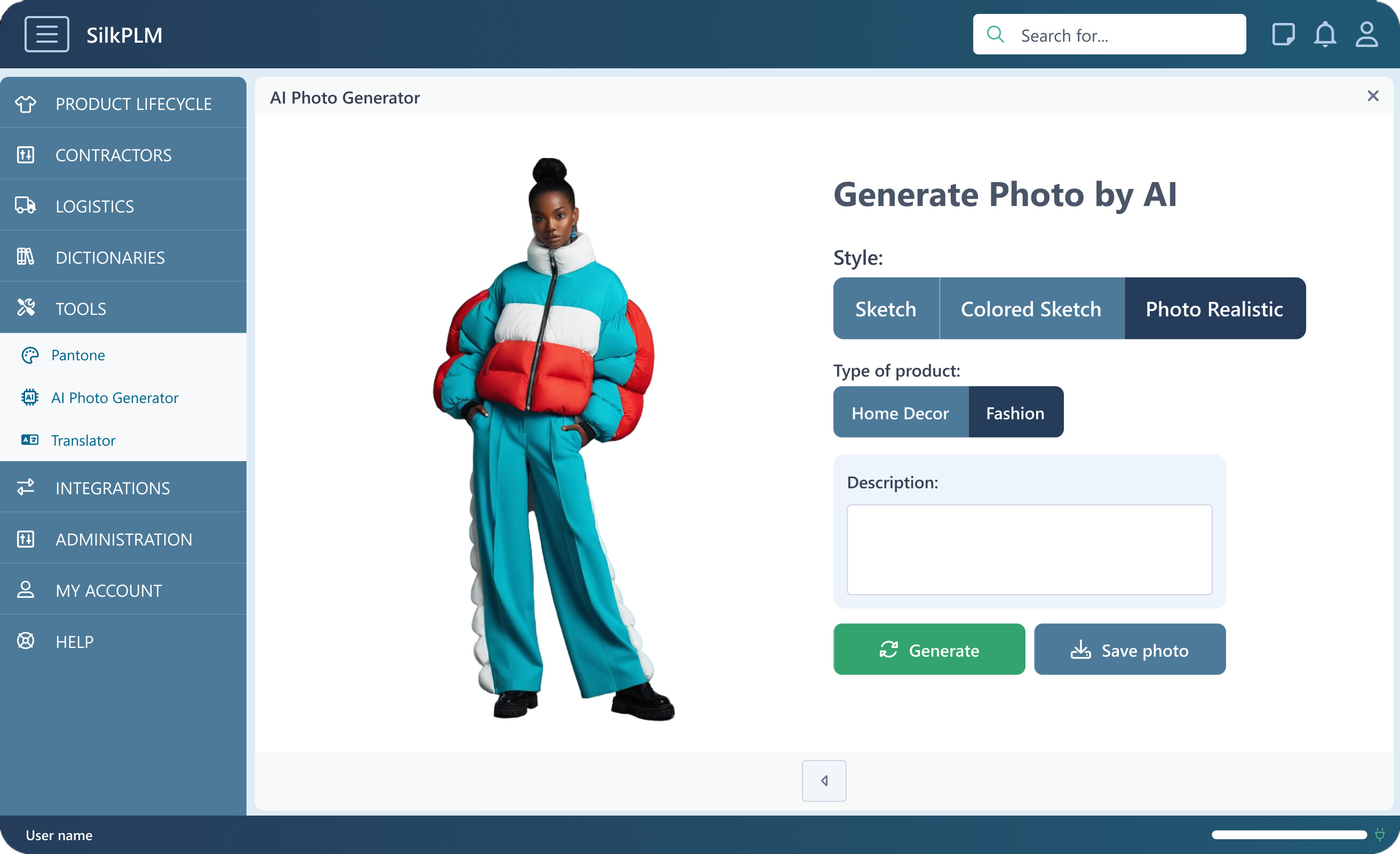

Nowadays, data is the cornerstone of a company’s competitiveness. Their collection and analysis allow you to gain an advantage over your industry rivals. Still, one factor that is also becoming rather popular is artificial intelligence.

And with us, you gain its powers.

SilkPLM AI features

Selecting us means you get artificial intelligence targeted especially for the retail industry. Particularly for the sectors of fashion and home décor.

So you gain:

- Creating product inspirations with the artificial intelligence model.

- Creating new products based on generated inspirations.

- Creating interesting e-commerce product. descriptions grounded on images and product data.

- Product cards automatically filling in.