- Time flies like crazy, it’s easy to miss something and teams can’t keep up

- I’m drowning in routine tasks, we need some automation

Does this sound familiar?

If so, you are not by yourself. Many businesses battle with inefficiency, poor communication, and repeated tasks that reduce output. Luckily, Product Lifecycle Management (PLM) technologies exist as a fix. Still, the journey begins here rather than finishes with the choice of PLM integration. The important question is:

What actions should be done at the very start to ensure effective and flawless deployment of PLM?

Let me define a key concept that will direct our conversation before delving into the specifics.

What is PLM Integration?

It is important to know what PLM integration means before starting the preparation steps. Integration of PLM systems with other business systems and processes is the process of establishing a seamless environment for managing product data across the whole lifetime by means of connections between them.

This connection guarantees consistent, current information that is easily available to all pertinent stakeholders, therefore facilitating improved decision-making and simplified processes.

1. Collaborative Implementation

Effective PLM implementation changes team dynamics rather than only providing software. Team cooperation is therefore absolutely essential to accomplish this. Although management may find great resonance in the justification for a PLM system, it is imperative to share these advantages with all the relevant teams.

Invite your teammates right away. Talk about their everyday difficulties and how a PLM system may help them solve them. This cooperative method guarantees that the technology is customized to satisfy real user demands rather than only the organizational theoretical goals.

Early on involvement of team members also helps to establish buy-in, therefore lowering resistance to change and promoting a more seamless transfer to the new system.

By working together, you could also find before unnoticed problems or inefficiencies. Early in the PLM setup process, addressing these can significantly improve system performance once put into use.

2. Process Mapping for PLM Integration

Process mapping comes second in terms of preparation for PLM integration.

This entails building graphic models of your present procedures to grasp flow of work through your company. Although this may sound simple, it can be difficult as most of this information may live in the imaginations of certain team members instead than being recorded policies.

Process mapping helps you not only to define the workflows but also spot areas for development, repetitions, and bottlenecks. Determining which processes the PLM system will cover and how the system may be set to support these operations successfully depend on this clarity.

Process mapping also shows the tools and systems now in use, therefore guiding your choice of integration with the new PLM system. This stage is absolutely essential to make sure the PLM deployment fits your current infrastructure, therefore reducing disturbance and optimizing the influence of the system.

Conclusion

Getting ready for PLM integration calls for more than simply selecting the correct program.

It’s about creating a strong basis by means of careful process mapping and team cooperation. Early involvement of your teams and visualizing your processes will help you to make sure your PLM system not only provides ongoing value to your company but also is used effectively.

Follow these steps, and you’ll be well on your way to integrating PLM in a way that works well.

You may also be interested in:

Fashion Labels: The Essential Guide for Clothing Brands

Fashion labels play a crucial role in your brand and shape how customers perceive your product. If you're launching a new product line and feel unsure about how to select the right labels, this guide will serve as your go-to resource!

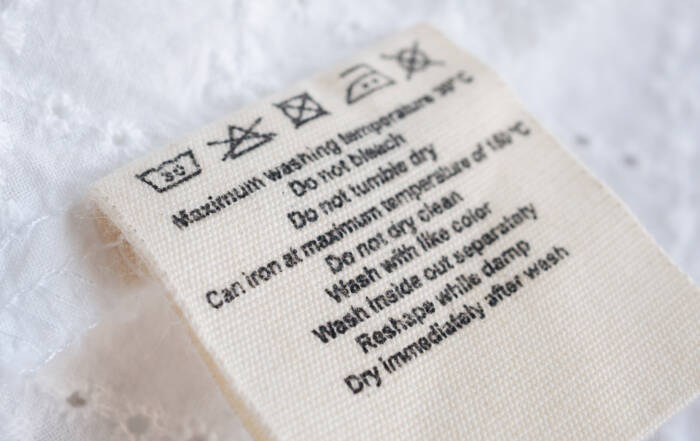

Guide to Care Labels for Fashion Brands: Compliance & Sustainability

Care labels are a vital communication tool for customer satisfaction, legal compliance, and reinforcing your brand values. Whether you're a fashion startup, e-commerce business, or independent designer, understanding care labels is non-negotiable.

Author:

Mariusz Wilczek

Marketing Specialist at SilkPLM