Have you heard about the Digital Product Passport (DPP) already? If not, let us explain it…

The backstory of every item you see on store shelves isn’t always obvious. The Digital Product Passport (DPP) is changing the retail industry by offering comprehensive insights into a product’s lifecycle at every stage. Discover what a DPP is and how it works!

What is a Digital Product Passport (DPP)?

DPP provides transparency and data on a product’s lifecycle, from sourcing to end-user experience. It includes all necessary information, such as composition, manufacturing details, and user care instructions. Importantly, it emphasizes sustainability and ethical practices, ensuring transparency in maintaining fair trade and decent work conditions throughout the manufacturing process.

The European Commission has set certain goals and expected outcomes related to the implementation of the DPP. That is why we have prepared a short infographic summarizing these goals. You can also check them on the official website of the European Commission

What exact information about the product will the DPP cover?

According to Cirpass.eu DPP should contain:

- A unique product identifier, as specified in the relevant regulations.

- The Global Trade Identification Number (GTIN) or similar codes for products or their parts.

- Relevant product codes, like TARIC codes for trade purposes.

- Compliance documents, such as declarations of conformity, technical documentation, or certificates.

- Information about substances of concern in the product.

- User manuals, instructions, warnings, or safety information.

- Details about the manufacturer.

- Identifiers for other responsible parties, especially those handling product certification.

- Identifiers for the facility where the product is made.

- Information about the importer.

- Optional EU Ecolabels for environmental performance.

- Information on the product’s performance based on relevant criteria.

- Instructions for consumers on how to install, use, maintain, and repair the product to reduce environmental impact and increase durability, plus how to return or dispose of it at end-of-life.

- Guidance for recycling or disposal facilities on disassembly and recycling at end-of-life.

- Any other information that could affect how others handle the product.

The EU will begin mandating Digital Product Passports (DPP) for high-impact items early in 2026, with the Ecodesign for Sustainable items Regulation (ESPR) already in effect as of July 18, 2024.

What products will be affected by ESPR?

ESPR will prioritize products with a high environmental impact, such as:

- Textiles (notably garments and footwear)

- Furniture

- Chemicals

- Batteries

- Consumer electronics

- Electronic devices

- Construction products

Source of screenshot: https://commission.europa.eu/energy-climate-change-environment/standards-tools-and-labels/products-labelling-rules-and-requirements/sustainable-products/ecodesign-sustainable-products-regulation_en#related-links

The Core Benefits of Digital Product Passport

- Transparency and traceability: Consumers can make wise choices knowing the source of products, manufacturing techniques, and disposal advice.

- Environmentalism and moral behavior: DPP guarantees that goods follow fair trade criteria and acceptable working conditions by offering knowledge on sustainable and ethical practices, hence strengthening the reputation of the brand and promoting consumer loyalty.

- Product management’s efficiency: Including DPP into Product Lifecycle Management (PLM) systems simplifies management and makes real-time updates possible as well as quick access to all product information in a single place.

Possible Future of DPP

Right now, DPP focuses primarily on sustainability data like product origin, materials utilized, and disposal guidelines. Still, it is always changing to incorporate more vital data for consumers and companies. There several ways the DPP might be carried out, including:

- QR Codes: Easily scanable by cellphones, QR codes give quick access to comprehensive product information.

- NFC Tags: Near Field Communication tags let devices wirelessly communicate data, hence improving user interaction and data access.

- RFID Tags: Radio frequency Modern tracking features of identification tags guarantee exact product monitoring all through the supply chain.

PLM and DPP Integration

Including DPP into PLM systems could be a revolutionary move for companies. Although there is considerable work involved in the initial setup, there are significant benefits in the long run:

- Real-time updates and thorough data collecting guarantee that product information is constantly accurate and current, thereby lowering errors and enhancing decision-making by means of this constant accuracy.

- DPP’s large amount of data makes it possible to do thorough analytics, which give useful information about how well products work, what customers like, and market trends.

- Teams may operate more effectively, concentrating on innovation and strategic initiatives rather than administrative chores, with all product information centralized and readily available.

- Embracing DPP and giving transparency and sustainability top priority can help companies stand out in the market and draw environmentally minded customers, therefore acquiring a competitive edge.

Conclusion

A potential game-changer for businesses could be integrating DPP with Product Lifecycle Management (PLM) systems.

Of course, at the first setup phase combining new technologies with current procedures calls some effort. Still, the advantages of data quality and insights—not to mention team comfort in daily operations—clearly exceed any costs.

You may also be interested in:

Fashion Labels: The Essential Guide for Clothing Brands

Fashion labels play a crucial role in your brand and shape how customers perceive your product. If you're launching a new product line and feel unsure about how to select the right labels, this guide will serve as your go-to resource!

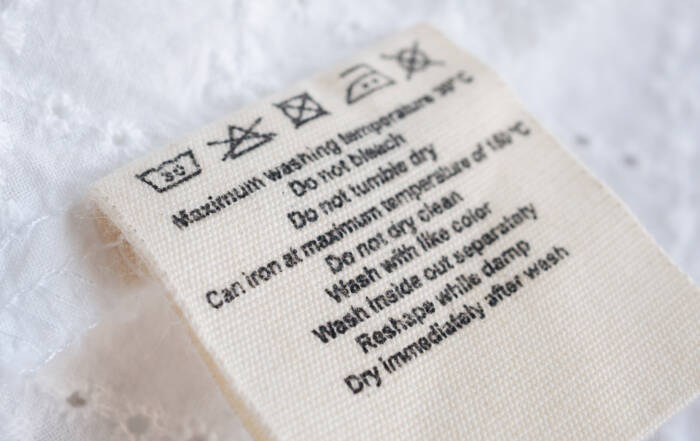

Guide to Care Labels for Fashion Brands: Compliance & Sustainability

Care labels are a vital communication tool for customer satisfaction, legal compliance, and reinforcing your brand values. Whether you're a fashion startup, e-commerce business, or independent designer, understanding care labels is non-negotiable.

Author:

Mariusz Wilczek

Marketing Specialist at SilkPLM