Knowledge base » Articles » PLM vs ERP: Top Differences and Benefits

PLM vs ERP: Top Differences and Benefits

Among the software solutions that help companies to stay competitive, boost output, and streamline procedures, there’s two crucial systems: ERP and PLM. Even though they have complementary functions, they cover many firm operations. Lets compare PLM vs ERP and learn about their benefits and differences.

What is PLM (Product Lifecycle Management)?

Product lifecycle management (PLM) is the all-encompassing system used to monitor the development, manufacturing, and final disposal of a product. By combining people, data, processes, and business systems, PLM provides companies and its extended partners with a strong basis for product knowledge.

5 Features of Product Lifecycle Management (PLM):

Product Data Management: Centralizes product information and documentation.

Process Management: Allows for the optimization and automation of procedures pertaining to products.

Collaboration Tools: Enhances collaboration among various departments and stakeholders.

Compliance Management: Ensures products meet industry standards and regulations.

Lifecycle Analytics: Provides insights into product performance and lifecycle stages.

What is ERP (Enterprise Resource Planning)?

ERP systems handle supply chain operations, risk management and compliance, procurement, accounting, and project management. Enterprise performance management tools found in a complete ERP system help to plan, budget, forecast, and report financial results.

5 Features of Enterprise Resource Planning (ERP):

Financial Management: Handles analysis, financial reporting, and accounting.

Supply Chain Management: Manages procurement, manufacturing, distribution, and logistics.

Human Resources Management: Manages employee information, payroll, recruitment, and performance.

Customer Relationship Management (CRM): Manages interactions with customers, sales, and service.

Business Intelligence: offers data analysis and reporting to back up decisions.

PLM vs ERP: Core Differences

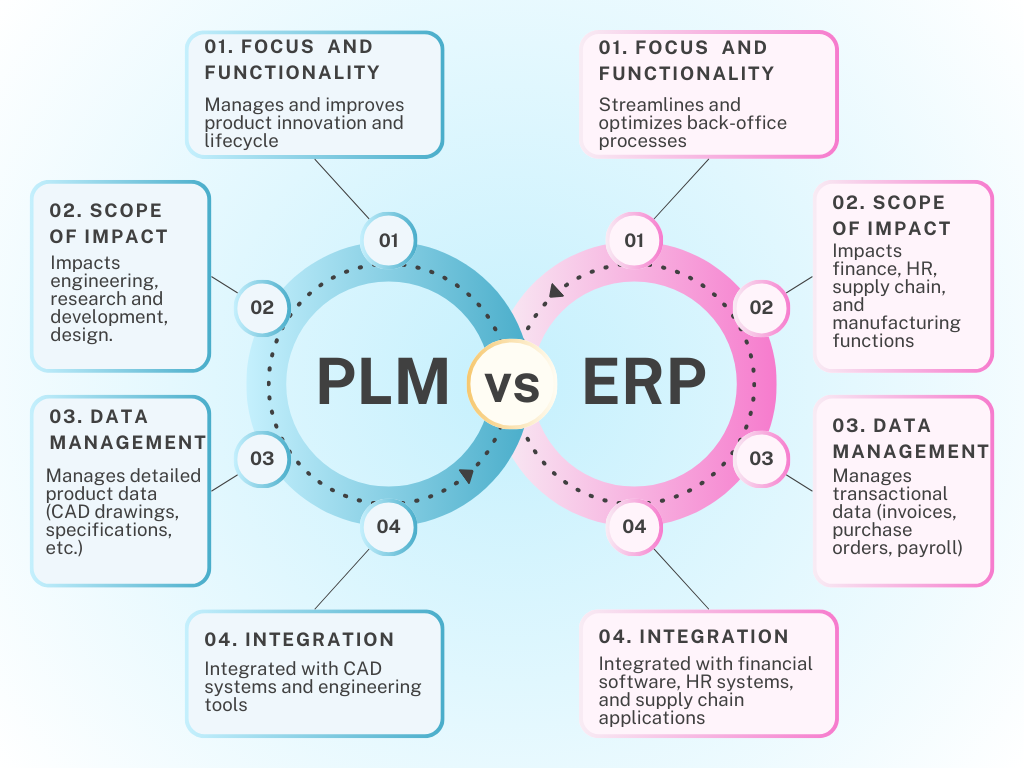

Focus and Functionality

- PLM: Mostly concerned in the process of product development. It seeks to control and raise product innovation and lifetimes of use.

- ERP: Focuses on a company’s transactional and operational sides. It seeks to simplify and maximize procedures in back offices.

Scope of Impact

- PLM: influences departments including engineering, R&D, and design involved in product creation and maintenance.

- ERP: affects manufacturing, supply chains, HR, finance, and manufacturing among other more general corporate operations.

Data Management

- PLM:Manages thorough product data including engineering change requests, CAD drawings, and specs in PLM.

- ERP: handles transactional data on business activities like payroll records, purchase orders, and invoicing.

Integration and Implementation

- PLM: Typically integrated with CAD systems and other engineering tools.

- ERP: Combined with a broad spectrum of business systems covering supply chains, HR tools, and financial software.

View our PLM vs ERP infographic for a quick rundown of the key points.

PLM vs ERP Benefits comparison

Benefits of PLM:

- Enhanced Product Innovation: Supports product development, boosting innovation.

- Improved Collaboration: Improves departmental interaction and teamwork.

- Compliance and Risk Management: Ensures products meet industry requirements.

- Reduced Time to Market: Accelerates product development, reducing time to market.

Benefits of ERP:

- Operational Efficiency: Streamlines business processes, improving overall efficiency.

- Cost Reduction: Reduces operational costs thanks to automation and optimized resource management.

- Improved Decision-Making: Provides real-time data and analytics for informed decision-making.

- Scalability: Supports business growth by providing scalable solutions.

Integrating PLM and ERP

Although PLM and ERP have different purposes, combining them will offer a complete answer for controlling business operations and product development.

By means of smooth data flow between the systems, this integration guarantees that every department has access to the newest information. Integration of PLM with ERP offers important advantages, including:

- Holistic View of Operations: Improves visibility and control by means of a consistent view of operational and product data.

- Improved Efficiency: Reduces data silos and duplicate procedures helps to increase general efficiency.

- Enhanced Collaboration: Improved cooperation between engineering and manufacturing teams results from this.

- Better Compliance and Quality Management: Improved compliance and quality control depend on accurate reflection of product data in operational systems, therefore supporting these areas.

Conclusion

ERP addresses the larger range of corporate processes while PLM concentrates on controlling the lifetime of a product. Companies can increase efficiency, creativity, and competitive advantage by properly combining the qualities of both systems.

The company that can use each tool to propel success and expansion will be the actual winner in the PLM vs ERP fight.

Frequently Asked Questions about PLM vs ERP

What is the main difference between PLM and ERP?

- ERP manages more general corporate operations and transactions; PLM concentrates on product development and lifecycle management.

Can a business integrate ERP and PLM systems?

- Yes, many businesses benefit from integrating both systems to meet all facets of their needs for product management and business operations.

PLM or ERP? Which system need a business start using first?

- The decision comes from the main needs of the business. While service-oriented organizations might give ERP top priority, manufacturing companies frequently begin with PLM.

How might a company benefit by combining ERP with PLM?

- Integration guarantees improved compliance and quality control, increases productivity, strengthens cooperation, and offers a whole perspective of operations.

Are ERP and PLM solutions appropriate for start-ups?

- PLM and ERP systems used to only be used by bigger companies, but now they both have scalable options that can help companies of all kinds.

Author:

Mariusz Wilczek

Marketing Specialist at SilkPLM